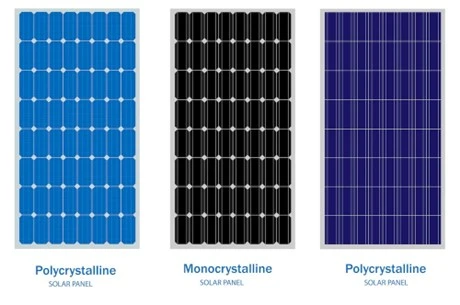

Differences between Monocrystalline and Polycrystalline Solar Panels

The Discovery of the Photoelectric Effect

In 1887, German physicist Heinrich Hertz observed that the arc between two electrodes connected to high voltage reached greater distances when illuminated with ultraviolet light compared to when left in the dark. This phenomenon, known as the photoelectric effect, occurs when a material irradiated with light energy generates an electric current, forming the basis of today's photovoltaic solar energy. Since its discovery, science has sought more efficient ways to convert light into electrical energy, leading to the development of solar cells used in photovoltaic panels. As a result, two main technologies have emerged: polycrystalline and monocrystalline, whose differences we will explore in this article.

Monocrystalline Solar Panels

The origin of a photovoltaic panel lies in silicon, one of the most abundant minerals on Earth, characterized by its grayish color and metallic luster. Silicon is a semiconductor, making it ideal for harnessing the photoelectric effect. Based on the manufacturing and purification processes, there are two common types of photovoltaic panels distinguished by the purity and quantity of silicon: monocrystalline and polycrystalline. The primary difference between them is that monocrystalline panels use silicon solar cells made from a single crystal.

Appearance

Monocrystalline panels have a dark, uniform appearance across their light incidence area.

Maintenance

Maintenance for monocrystalline modules is similar to other technologies. Professionals usually recommend cleaning the panels with water and a small amount of soap, ensuring a proper rinse. It's important not to use harsh cleaning products that could damage the cells; water and soap suffice to keep the panel in good condition, regardless of whether it's monocrystalline or not.

Efficiency

Efficiency refers to the amount of energy a module can produce per surface area. Monocrystalline panels generally exceed 21% efficiency due to the high purity of silicon and single-crystal composition, which allows electrons greater mobility, thereby reducing energy losses.

Durability

Technological advancements and investment in R&D have extended the lifespan of these panels to about 25 years, depending on the manufacturer, assuming proper maintenance and monitoring.

Price

Monocrystalline panels are more expensive than polycrystalline ones due to the higher purity of silicon required, translating to higher manufacturing and raw material costs. For instance, a 200W monocrystalline module may cost around €150, while a similar polycrystalline module might be €25 to €40 cheaper.

Polycrystalline Solar Panels

The key technological difference between polycrystalline and monocrystalline panels is the manufacturing process. For polycrystalline panels, silicon from various sources is melted and placed in molds to cut into solar cells. Melting the silicon introduces impurities, reducing efficiency compared to monocrystalline panels.

Appearance

Polycrystalline panels are easy to identify due to their varied dark blue tones resulting from the mixed silicon crystals.

Maintenance

The recommended maintenance for polycrystalline panels is the same as for monocrystalline ones.

Efficiency

Polycrystalline panels have lower efficiency, ranging from 12% to 18%, due to the less pure silicon used in their manufacture. However, they perform better at high temperatures, minimizing energy losses due to heat.

Durability

Polycrystalline panels have a similar lifespan to monocrystalline ones, typically around 20-25 years.

Price

Polycrystalline panels are cheaper than monocrystalline ones because of the lower purity of silicon and reduced manufacturing costs.

Choosing the Right Solar Panel

When considering a photovoltaic self-consumption project, factors such as available roof space, financial capacity, location, and the characteristics of each panel type are crucial.

Monocrystalline Panels

Monocrystalline panels are suitable for locations with limited space, good solar resources, and no extreme temperatures, where the owner can afford a higher initial investment for more efficient technology.

Polycrystalline Panels

Polycrystalline panels are ideal for projects with more available space. They can achieve the same production with more panels compared to monocrystalline ones, making them suitable for larger installations and homes with more available land or roof space.Ultimately, choosing between monocrystalline and polycrystalline panels involves balancing efficiency, profitability, and initial cost.

Conclusion

In conclusion, the choice between monocrystalline and polycrystalline solar panels depends on specific project needs and conditions. By considering factors such as space, budget, and efficiency requirements, one can find the right balance to achieve optimal energy production and cost-effectiveness.

Source: edpenergía.es